FLEXI-DISC®

Move Fragile Bulk Materials

![]()

![]()

Handle friable materials gently, efficiently, dust-free

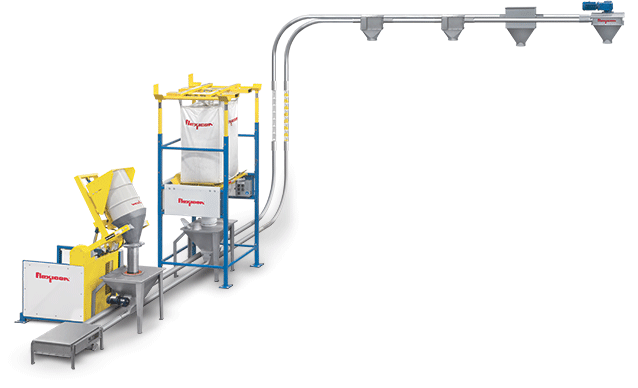

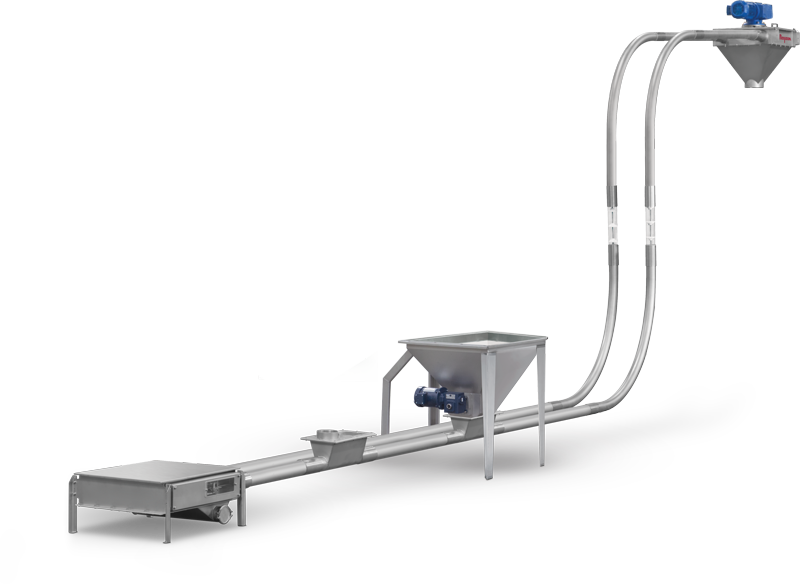

FLEXI-DISC® Tubular Cable Conveyors (also known as Disc Conveyors and Drag Conveyors) gently slide bulk materials through smooth stainless steel tubing using low-friction polymer discs attached to stainless steel cable. The discs and cable are driven by a wheel at one end of the circuit, and put under tension by a wheel at the other end. This design allows

single or multiple inlets and outlets, and the routing of conveyor tubing horizontally, vertically or at any angle, through small holes in walls or ceilings. Because components are modular, inlets and outlets can be added, removed or relocated, and the circuit lengthened, shortened or re-routed as needs change.

Materials ideally suited to FLEXI-DISC conveyors include virtually all dried beans, cereals, coffees, dried fruits, frozen vegetables, grains, nuts, pet foods, seeds, snack foods, dried spices, teas, and other fragile/friable food products. Typical non-foods include prills, pelletized products, and dried plant products such as tobacco or hemp.

Go to expanded materials page >>

Features

- Gentle conveying of friable materials containing particles of disparate sizes, shapes and bulk densities, with no separation of blended materials

- Transfers material from single or multiple inlets to single or multiple outlets (ideal for packaging lines)

- Modular components allow changes in conveyor routing, length, and the number and position of inlets and outlets

- Low power requirements per volume of material conveyed

- Air-free conveying eliminates need for blowers and filtration equipment

- Maintains temperature and moisture levels of material being conveyed

- Enclosed system contains dust, prevents contamination

- Stainless steel components finished to food, pharmaceutical or industrial standards

- Evacuates material, minimizing waste and facilitating rapid cleaning

- Available with quick-clean accessories

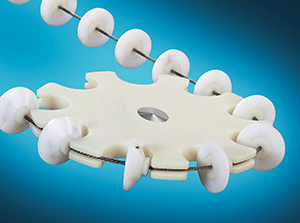

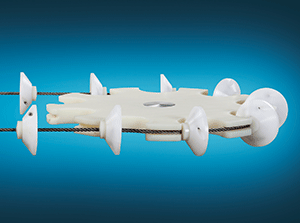

CABLE, DISCS AND TUBING

Tight tolerance, high-strength discs of engineered polymers in 4 and 6 in. (100 and 150 mm) diameters available on 304 and 316 stainless steel cable, including polymer-coated.

The FLEXI-DISC® Cable-Disc Assembly is highly engineered and thoroughly proven to simultaneously deliver unsurpassed efficiency, extreme durability and ultra-gentle product handling.

Discs are available in a range of designs and high-strength engineered polymers to suit a broad variety of materials. The discs are designed for smooth passage through bends in the tubing circuit, and with clearances to the tube wall designed to eliminate or minimize product degradation. Low friction surfaces allow the discs to glide efficiently within the smooth stainless steel tubing, while minimizing product hang-up and allowing easy cleaning.

The FLEXI-DISC Cable is offered in stainless steel, and is available polymer-coated.

FLEXI-DISC Straight Tubing, Elbows and Couplings are offered in 304 or 316 stainless steel finished to industrial or sanitary standards.

Clear Inspection Tubing can be located in any straight run of tubing to visually monitor conveyor performance.

Sanitary Systems

FLEXI-DISC Conveyors are fully enclosed, preventing contamination of the product and plant environment. At the end of a conveying cycle, the discs evacuate the conveyor tubing of material, virtually eliminating wasted product and facilitating rapid, thorough sanitizing.

Sanitary specifications include polymer-coated or uncoated 304 or 316 stainless steel cable.

All tubing, material inlets, material outlets and ancillary metallic components are of 304 or 316 stainless steel with continuous welds ground and polished to food, pharmaceutical or industrial standards.

Wet or dry cleaning accessories can be quickly attached to the FLEXI-DISC cable to minimize downtime between changeovers.

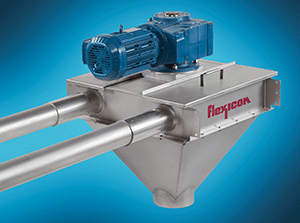

DRIVES AND TENSIONERS

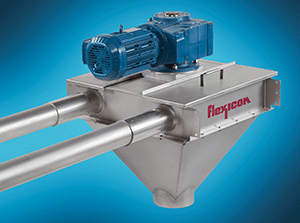

Drive System shown with optional discharge cone.

The Drive System rotates a drive wheel which changes the cable's direction of travel by 180° and circulates the cable and discs at relatively slow speed through the conveyor circuit. With optional discharge cone (shown), it can also serve as the only discharge point, or as the final discharge. See OUTLETS page

Automatic Cable Tensioner keeps cable and disc assembly taut.

The Automatic Cable Tensioner contains a wheel that reverses the direction of cable while keeping it taut throughout the conveyor circuit. This ultra-compact, simplified design is smaller than conventional units, and positions the Tension Inspection Window at an easy viewing angle.

MATERIAL INLETS

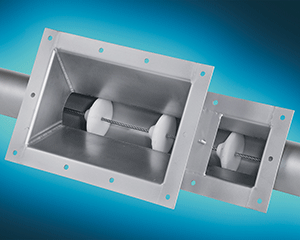

Metered Inlet Adapter

The Metered Inlet Adapter is equipped with dual adjustable metering gates that are infinitely adjustable up to fully-opened position using external locking levers, controlling the rate at which material enters the conveyor tube. The target fill rate of the conveyor can additionally be controlled by increasing or decreasing the speed of the cable and disc assembly.

Non-Metered Inlet Adapter

The Non-Metered Inlet Adapter funnels incoming material at a feed rate determined by upstream processes equipped with a metered discharge to achieve the target feed rate. For non-metered inlets, the linear speed of the cable and disc assembly determines the disc pocket fill percentage.

Metered (above) and Non-Metered (right) Inlet Adapters are offered with universal flanged inlets for connection to flanged outlets (or downspouts) of bag dump stations, bulk bag dischargers, silos or other material sources.

Metered and Non-Metered Inlets are available with optional floor hoppers (shown) and with Bulk Bag Dischargers, Drum/Box/Container Dumpers, Bag Dump Stations, Storage Vessels and other equipment to supply the conveyor with material. Also see System Layouts and Integrated Systems

MATERIAL OUTLETS

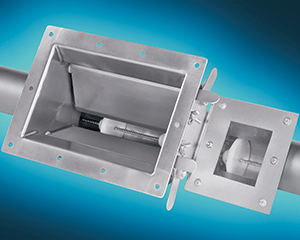

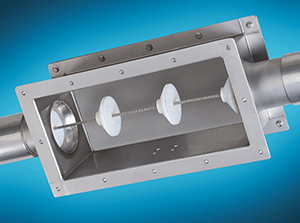

Inline Tubular Discharge Valves

Inline Tubular Discharge Valves enable conveyor circuits to dispense material at one or multiple locations through round spouts for connection to a flexible downspout, or flanged outlets for connection to process or packaging equipment. Tubular Discharge Valves contain a U-shaped trough rotated by a pneumatic actuator, allowing complete material discharge at a mid-point of the conveyor, or total carry-over to a downstream outlet. With the trough in the downward (open) position, material discharges fully. Rotated 180° to the upward (fully closed) position, material is conveyed through the discharge valve.

Tubular Discharge Valve in open position.

Full-Flow Inline Discharges

Full-Flow Inline Discharges are devoid of valves and actuators, providing an unrestricted, final discharge through a flexible downspout or a flanged outlet of process or packaging equipment. An air knife or disc ramp can be employed in Full-Flow Inline Discharges to dislodge material from the cable and discs.

Full-Flow Inline Discharge serves as the final discharge point to evacuate the conveyor.

Drive Systems with Optional Discharge Cones

Drive System is available with an optional discharge cone (shown), which can serve as the only discharge point, or as the final discharge in lieu of a Full-Flow Discharge.

Drive System with Optional Discharge Cone can also serve as the final discharge point to evacuate the conveyor.

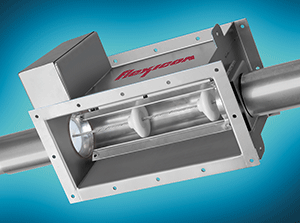

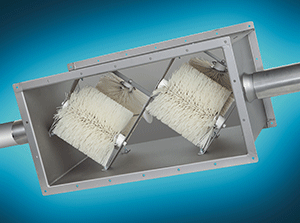

Brush Boxes

Brush Boxes contain one or two (shown) pair of cylindrical brushes that converge at the centerline of the cable. Discs passing through the brush box deflect the stiff bristles, dislodging any residual material adhered to the cable and disc assembly.

Brush Box dislodges residual material from cable and discs automatically.

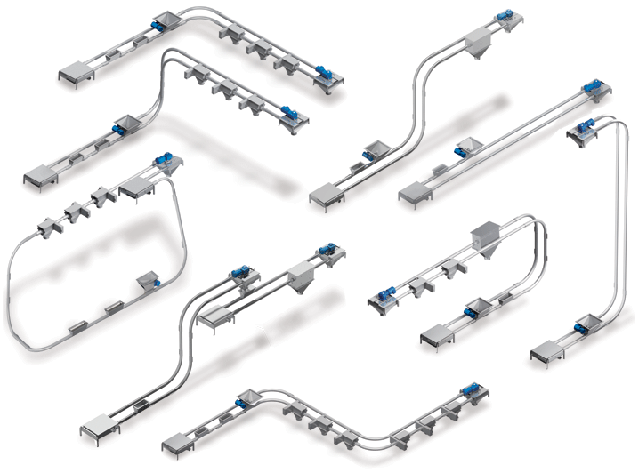

CONFIGURATIONS

System Layouts and Integrated Systems

Stand-alone and self-contained systems

FLEXI-DISC conveyors can be routed vertically, horizontally or at any angle, through small holes in walls or ceilings. Conveyor configurations range from basic systems with one material inlet and one discharge, to systems routed in several directions over hundreds of feet/meters, with multiple material inlets and outlets as shown in the above examples.

These systems can source material from multiple plant locations, and deliver it selectively to storage vessels, packaging machines and/or downstream process equipment.

In addition to stand-alone systems, all FLEXI-DISC conveyors are available integrated with new or existing upstream and/or downstream equipment from Flexicon and others, including but not limited to: Inlet Hoppers, Bulk Bag Dischargers, Drum Dumpers, Box/Container Dumpers, Bag Dump Stations, Bulk Bag Fillers, Screeners, Blenders, Magnetic Separators, Packaging Machines, Feeders, Dryers/Coolers, Crushers/Grinders, Storage Vessels and other process equipment — all engineered, automated and guaranteed to perform by Flexicon.

Total systems integration

In addition to stand-alone and self-contained FLEXI-DISC conveyor systems described above, Flexicon offers plant-wide bulk handling systems that can integrate and automate your facility's entire bulk handling and processing system, or any portion thereof — without the high cost, complexity or risk associated with large scale projects. Flexicon can assume single-source responsibility for engineering, integrating, automating and supporting your project, and guarantee its performance, alleviating you of the burden and risk of designing your system, coordinating multiple suppliers, integrating components, trouble-shooting start-up and assuming responsibility for system performance.

Flexicon can draw from its own extensive range of equipment, as well as the equipment of other manufacturers, assuring you of the optimum solution to your bulk handling and processing problem. From evaluating your material in state-of-the-art test laboratories and supplying your system on time, to assisting with installation and servicing on-site, no other manufacturer is more devoted to your company's success — and to yours — as Flexicon.

MATERIALS

Coffees (Green, Roasted and Ground) and Teas (Including Blends)

Food Products

Bacon bits

Beans: Azuki (dried)

Beans: Cocoa (dried)

Beans: Fava (dried)

Beans: Kidney (dried)

Beans: Lentils (dried)

Beans: Lima (dried)

Beans: Pinto (dried)

Beans: Soybeans (dried)

Breadcrumbs

Couscous

Cereal: Dried fruit

Cereal: Flakes

Cereal: Formed shapes

Cereal: Grains

Coffee: Blended

Coffee: Freeze dried

Coffee: Green beans (dried)

Coffee: Ground

Coffee: Instant

Coffee: Roasted

Coffee: Whole bean

Dried fruit: Apples

Dried fruit: Bananas

Dried fruit: Pineapple

Flour

Frozen: Blueberries

Frozen: Broccoli

Frozen: Cauliflower

Frozen: Cherries

Frozen: Corn

Frozen: Green beans

Frozen: Peas

Frozen: Strawberries

Grains: Barley

Grains: Corn

Grains: Oats

Grains: Rice

Grains: Wheat

Hazelnuts

Malt

Nuts: Almonds

Nuts: Brazil nuts

Nuts: Cashews

Nuts: Filberts

Nuts: Macadamia

Nuts: Peanuts

Nuts: Pecans

Nuts: Pistachios

Nuts: Walnuts

Pasta in many forms

Peas: Black eyed (dried)

Peas: Chickpeas (dried)

Peas: Dixie Lee (dried)

Peas: Snap peas (dried)

Peas: Sweet peas (dried)

Peas: Yellow peas (dried)

Pet foods: Chunks

Pet foods: Formed shapes

Pet foods: Kibble

Pet foods: Pellets

Pistachio Meats

Seeds: Bird seed

Seeds: Carrot seed

Seeds: Cottonseed

Seeds: Dill seed

Seeds: Flax seed

Seeds: Grass seed

Seeds: Mustard seed

Seeds: Pepper seed

Seeds: Sesame seed

Seeds: Tomato seed

Snack foods

Spices: Basil (dried)

Spices: Chives (dried)

Spices: Coriander (dried)

Spices: Cumin (dried)

Spices: Garlic (dried)

Spices: Ginger (dried)

Spices: Mint (dried)

Spices: Nutmeg (dried)

Spices: Oregano (dried)

Spices: Paprika (dried)

Spices: Parsley (dried)

Spices: Pepper (dried)

Spices: Rosemary (dried)

Spices: Saffron (dried)

Spices: Sage (dried)

Spices: Thyme (dried)

Spices: Vanilla (dried)

Sunflower Seeds

Teas: Black tea

Teas: Green tea

Teas: Oolong tea

Teas: White tea

Teas: Yellow tea

TiO2

Trail Mix