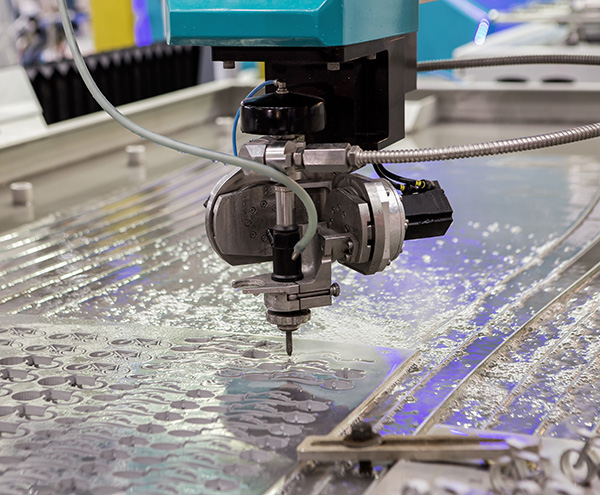

METALWORKING

TYPICAL END PRODUCTS

Typical Metalworking products manufactured using powder and bulk ingredients include:

- Alloy Products

- Aluminum Die-Castings

- Bakeware Molds

- Bearings

- Briners

- Castings

- Connectors & Pins

- Control Arms

- Cutting Tools

- Electrometallurgical Products

- Fittings

- Fluxes

- Forks & Rings

- Gears

- Jewelry

- Medical Device Components

- Nails

- Nonferrous Die-Castings

- Pipes

- Pistons

- Porcelain Enamel

- Rods & Cylinders

- Rolls & Roll Sleeves

- Silverware

- Spikes

- Superalloy Ingots

- Thermocouples

- Transmission Shafts

- Tubes

- Valves & Pump Components

- Vessels

BULK MATERIAL CHARACTERISTICS

Bulk ingredients used in Metalworking run the gamut, from dry to oily, free-flowing to non-free-flowing and powders to large pieces. Typical material characteristics include:

- Abrasive

- Dusty

- Hazardous

- Hygroscopic

- Free- and semi-free flowing

- Corrosive

- Materials that pack, cake or smear

TYPICAL BULK MATERIALS HANDLED:

- Aluminum

- Aluminum Hydrate

- Aluminum Oxide

- Aluminum Stearate

- Ammonium Perchlorate

- Anhydrous Magnesium Chloride

- Anthracite

- Bentonite Clay

- Bisphenol A

- Calcium Stearate

- Carbon Black

- Carnauba Wax

- Cobalt Sulfate

- Diatomaceous Earth

- Dispal Alumina

- Electric Arc Furnace Dust

- FEP Pellets

- Fused Silica

- Garnet

- Hydrated Lime

- Hydrocarbon Resins

- Hydrotalcite

- Manganese Sulfide

- Metal Shavings

- Molybdenum Trioxide

- Petroleum Hydrocarbon

- Platinum

- Potassium Carbonate

- Potassium Nitrate

- Powdered Lime

- Salt

- Sand

- Silicon Dioxide

- Soda Ash

- Sodium Hydroxide

- Sodium Nitrate

- Stearic Acid

- Tantalum

- Terephthalic Acid

- Titanium

- Tungsten

- Tungsten Ore

- Urea Resin

- Zinc Oxide Molybdenum

- Zirconium

Don't see your material? With over 25,000 installations worldwide and thousands of years of combined experience, Flexicon has most likely handled your material successfully many times over.

Contact Flexicon to discuss your application in more detail.

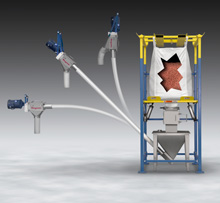

FLEXICON EQUIPMENT FOR

BULK METALWORKING PRODUCTS

Stand-alone units to engineered systems, Flexicon equipment can integrate with other manufacturers' equipment, unload, convey or fill large volumes of materials rapidly, reduce environmental hazards, promote flow, contain product, reduce product degradation, create filtration systems, suppress and collect dust and improve worker safety.

Examples include:

SPECIALIZED EQUIPMENT THAT MEETS YOUR BULK HANDLING NEEDS

- Reduce wash-down time

- Eliminate cross-contamination between changeovers

- Prevent plant and product contamination

- Contain dust

- Verify cleanliness