Click to enlarge

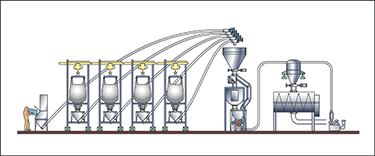

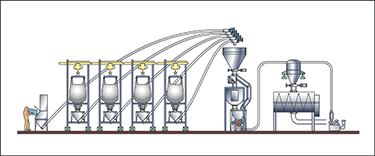

Click to enlargeFigure 1: A combination of flexible screw and pneumatic conveying meets process requirements, with five flexible screw conveyors transporting ingredients to a weigh-batching system, and vacuum pneumatic conveying taking weighed and mixed dry ingredients to wet blending.

Click to enlarge

Click to enlargeFigure 2: Bulk bag unloaders utilize a proprietary bag-spout interface that creates a high-integrity sealed connection to contain dust and prevent contamination of the product and plant environment. A manual bag dump station with dust collection (center) protects workers and prevents plant contamination.

Click to enlarge

Click to enlargeFigure 3: Flexible screw conveyors slow to dribble speed for pinpoint accuracy in measurement of ingredients to within 1% of recipe targets, and also isolate the powders from moisture in plant air.

Click to enlarge

Click to enlargeFigure 4: An automated control system manages the entire process according to pre-programmed batch recipes.

Click to enlarge

Click to enlargeFigure 5: A filter-receiver with reverse- pulse filter cleaning continuously and efficiently separates the powder from the vacuum pneumatic system, dropping process feed into the wet mixer.

Click to enlarge

Click to enlarge(L-R) Five flexible screw conveyors transport powders from a bag dump station and four bulk bag dischargers to a gain-in-weight hopper mounted on load cells. Three of the ingredients are weigh batched, gravity discharged from the hopper into a dry mixer, and metered into a pneumatic conveying line that terminates at a filter receiver which discharges into a wet blender. The other two ingredients are weigh batched in the same manner, but they bypass the dry blending stage, and instead are metered directly into the pneumatic conveyor line that terminates at the filter receiver discharging into the wet blender, where all five ingredients are combined.

Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge