Pneumatic conveyors transport bulk materials through enclosed pipelines using air or gas streams, effectively moving powders, granules, and small particles. Flexicon’s PNEUMATI-CON® dilute phase pneumatic conveying systems are custom-engineered to handle a wide range of applications, offering flexible routing and the ability to transport materials over varying distances, both vertically and horizontally.

Click and drag product to rotate.

Learn everything you need to know about Flexicon® pneumatic conveying systems.

Flexicon’s PNEUMATI-CON® dilute phase pneumatic conveying systems are custom-engineered to handle a wide range of bulk materials, from single-point “up-and-in” installations to cross-plant systems with multiple pick-up and discharge points. This conveying application moves bulk materials that are suspended in an air stream that is introduced by a positive pressure blower upstream of material intake points, or pulled through the system by a vacuum pump downstream of material discharge points. Material is separated from the air at the use point, then discharged on a batch basis via butterfly or slide gate valves, or continuously via rotary airlock valves.

Vacuum dilute phase pneumatic conveying systems are ideal for transferring materials from multiple sources such as storage vessels, process equipment, trucks, and railcars to one or more destinations with minimal heat impact and superior leak containment, making them especially suitable for handling hazardous or sensitive materials. These systems use a downstream vacuum pump to create a negative pressure differential in the conveying line, allowing for easy material pickup via rotary airlock valves, flexible screw conveyors, handheld wands, or flood feed adapters, and discharge through filter receivers or cyclone separators positioned above process equipment or storage points. Additionally, vacuum conveying supports direct feeding into enclosed vessels like blenders and reactors under vacuum, streamlining operations by eliminating the need for individual dust collection units at each discharge location.

Positive pressure dilute phase pneumatic conveying systems are typically used to transport bulk materials to one or multiple destinations over longer distances and with greater capacity than vacuum systems. These systems typically rely on a positive displacement blower with single or multiple downstream material entry points, each metering product into conveying lines through a rotary airlock valve that maintains the pressure differential between the ambient atmosphere and the conveying line. Material and air blown through the line exit at one or more use points where they are separated by a filter receiver or cyclone separator, or fed directly into process vessels vented to downstream dust collection devices. Pressure systems offer higher efficiency than vacuum systems, can convey over longer distances, and can blow directly into process and storage vessels without the need for a rotary airlock valve.

ROTARY AIRLOCK VALVES WITH FLOW-THROUGH PICK-UP ADAPTERS (Pressure and Vacuum Systems)

Rotary airlock valves with flow-through pick-up adapters are used in pressure and vacuum systems for controlled metering of material into the conveying system, and maintaining the pressure differential between the conveying line and ambient atmosphere.

NON-FLOW-THROUGH PICK-UP ADAPTERS (Vacuum Systems)

Material can be introduced into vacuum conveyor lines via non-flow-through (flood-feed) pick-up adapters, which are typically used at pick-up points where lower volumes of material are fed manually.

WANDS (Vacuum Systems)

Handheld pickup wands connected to vacuum conveying lines via flexible hose allow operators to vacuum material directly from containers such as Gaylords, drums, paper bags, and barrels.

FILTER RECEIVERS (Pressure and Vacuum Systems)

Flexicon filter receivers efficiently separate solids from the air stream using filter media and gravity, making them well-suited for applications involving fine particles or where dust containment is critical. Positioned above material use points, they feature reverse pulse jet cleaning that dislodges accumulated dust from filter surfaces, ensuring continuous, reliable performance and clean operation.

CYCLONE SEPARATORS (Pressure and Vacuum Systems)

Cyclone separators use centrifugal force and gravity to remove solids from the conveying air stream, making them a good choice for materials with larger particle sizes that are less prone to dusting. While filters are not typically required, they can be added downstream as a secondary measure to capture airborne particles.

FILL/PASS VALVES (Pressure and Vacuum Systems)

Fill/pass valves enable direct discharge of material into one or more process vessels, or distribution to multiple destinations along a shared conveying line. After the final fill/pass valve, the line is usually routed back to the original source or to a dust collection system.

DIRECTLY INTO PROCESS VESSELS (Pressure and Vacuum Systems)

Both pressure and vacuum systems can feed material straight into enclosed process vessels such as blenders and reactors, which are vented to downstream dust collection devices. This configuration eliminates the need for individual filter receivers at each discharge point.

Flex-tube, wye and fill/pass diverters provide smooth transitions and selective routing to facilitate conveyor line configurations to meet any plant layout requirements. Line diverters enable more complex conveying line configurations by allowing materials to converge from multiple sources or diverge to various destinations, while fill/pass diverters support inline delivery along a single, continuous conveying path. Regardless of your plant layout or material flow requirements, the proper application of these valves ensures an efficient and effective conveying system.

ROTARY AIRLOCK VALVES IN ALL POPULAR DESIGNS AND SIZES

FILTER RECEIVERS FOR LOW TO HIGH CAPACITY APPLICATIONS

CYCLONE SEPARATORS FOR LOW TO HIGH CAPACITY APPLICATIONS

SILOS, DAY BINS AND OTHER STORAGE VESSELS

Silos, day bins, and other storage vessels provide secure, dependable storage for larger quantities of bulk materials for downstream processes. Available in carbon steel or stainless steel with industrial or sanitary finishes, these vessels are designed for durability and seamless integration within pneumatic conveying systems.

HAND-HELD PICK-UP WANDS

Automation and Controls

Easy Line Routing

With the ability to route conveyor lines vertically and in any horizontal direction, PNEUMATI-CON® systems provide unmatched layout flexibility. They can span short or long distances and pass through small openings in walls or ceilings, making them ideal for production environments with limited space and existing equipment.

Long Conveying Lengths

Pneumatic conveyors are an optimal solution for efficiently transporting materials over long distances in bulk material handling systems. Flexicon’s design capabilities ensure reliable performance across extended conveying lengths, minimizing operational downtime.

Multiple Inlets and Outlets

Flexicon pneumatic conveying systems are engineered to handle multiple material inlets and outlets within a single conveyor, enabling efficient and flexible routing and delivering high performance across a wide range of industries.

Total Evacuation

PNEUMATI-CON® systems completely evacuate both the source material vessel and conveyor line, virtually eliminating cross-contamination in applications with various materials. Pneumatic conveying systems ensure precise and complete material transfer, making them ideal for weigh batching applications where accurate delivery of weighed ingredients is critical. By fully transporting materials, these systems enhance batch quality and minimize waste, optimizing production efficiency.

Diversity of Products

Flexicon pneumatic conveyors offer versatility, capable of handling powders with a wide range of bulk densities, as well as flakes, pellets, capsules, tablets, and other material forms. This flexibility makes it easy to transport multiple ingredients using a single system.

Wide Capacity Range

With a PNEUMATI-CON conveyor, throughput can range from just a few pounds to tons per hour, feeding everything from small packaging lines to large silos and railcars. Even when feed rates fluctuate significantly, the system remains protected from overloading or underloading, ensuring reliable performance.

ENCLOSED SYSTEM PREVENTS CONTAMINATION

Designed for clean and secure operation, PNEUMATI-CON® conveying systems maintain a fully enclosed, dust-free environment. This helps prevent contamination of both the product and the plant, making them well-suited for transferring dusty materials.

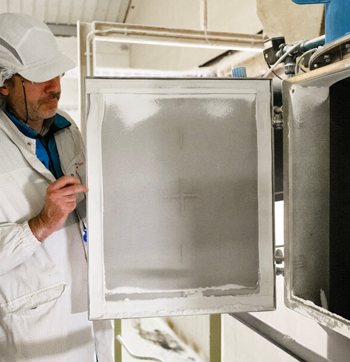

EASE OF MAINTENANCE

Flexicon PNEUMATI-CON® systems are designed for easy maintenance, featuring filter receivers with convenient access doors and inspection ports. Rotary airlock valves can be equipped with optional rotor support bars, allowing straightforward access for cleaning and inspection to help reduce downtime and improve efficiency. In vacuum conveying applications, ultra-low maintenance Flexicon flexible screw conveyors can be used to meter product into the system.

MEET INDUSTRIAL AND SANITARY STANDARDS

PNEUMATI-CON® conveying systems are available in carbon steel with rugged industrial finishes or stainless steel designed to meet the standards of food, dairy, pharmaceutical, and other sanitary applications.

Pneumatic conveyors are well-suited for a variety of applications and plant environments. They can be paired with a broad range of upstream and downstream equipment including the Flexicon product line.

Pneumatic conveying systems are a reliable solution for transferring materials from bulk bag dischargers to downstream processes with minimal dust, while ensuring a consistent flow of material.

Pairing pneumatic conveying systems with a Bag Dump Station offers a simple method to introduce materials into your process while effectively containing dust and maintaining a clean work environment.

Pneumatic conveying offers precise, long-distance transfer of weighed batches to downstream processes enabling flexibility of plant layouts.

Pneumatic conveyors feed multiple ingredients long-distances into mixers for batching and blending systems enabling precise formulations and consistent product quality.

With fully enclosed, dust-tight operation, pneumatic conveying systems efficiently transfer bulk solids during truck and rail car loading or unloading, minimizing product loss while ensuring clean, safe, and reliable material movement.

Flexicon can design your pneumatic conveying system to meet your unique needs. Explore some of the configurations we have developed for customers like you.

Stone, Clay Glass, Ceramics Products

– Samantha Bucknall, UK Group Performance Manager at LKAB

Food Products Facilities

– Jean-Paul Amyot, Packaging Workshop Manager at Tereos

How does the Flexicon® Pneumatic Conveyor stack up against flexible screw and tubular cable conveying systems? Find out which one meets your application requirements.

"*" indicates required fields