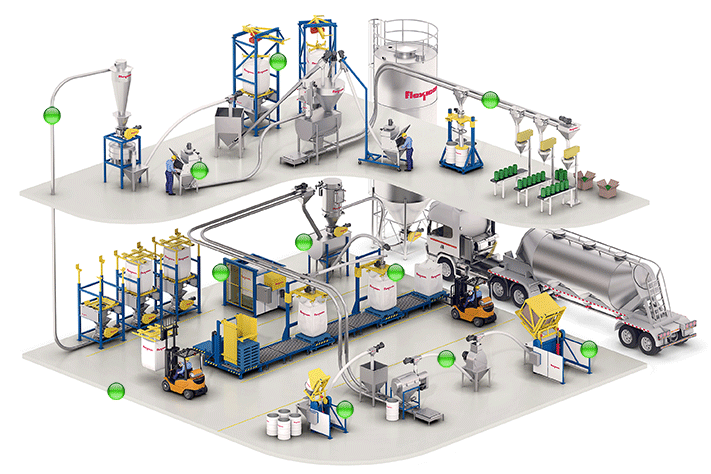

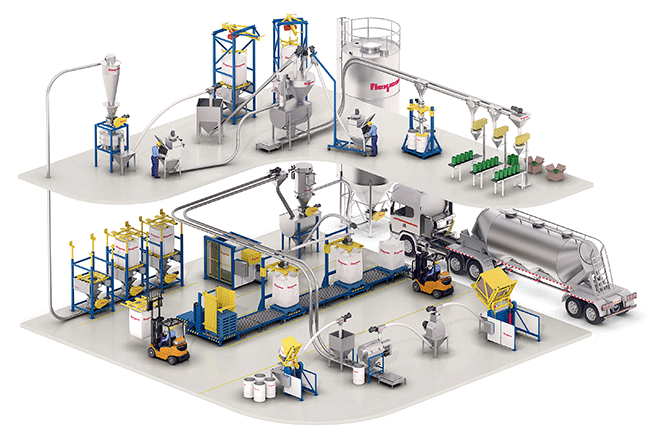

Flexicon Corporation is a world leader in the design and manufacture of bulk handling equipment and custom-engineered and integrated plant-wide systems. Flexicon products range from individual equipment to automated systems that source bulk material from interior and exterior plant locations, transport it between process equipment and storage vessels, weigh it, blend it, feed it to packaging lines, extruders, molding machines and storage vessels, and load it into railcars and trailers.

Choose from a broad range of reliable, high performance equipment in carbon steel with durable industrial finishes, or in stainless steel designed and constructed to industrial, food, dairy or pharmaceutical standards:

Flexicon can also custom-engineer automated, plant-wide bulk handling and processing systems that integrate Flexicon equipment with bulk handling and process equipment of other manufacturers:

- Gravimetric/Volumetric Feeders

- Silos and other storage vessels

- Dryers/Coolers

- Mixers/Blenders

- Screeners

- Crushers/Grinders

- Packaging Machines

- Other bulk processing equipment

Flexicon can custom engineer automated, plant-wide bulk handling and process systems that integrate Flexicon equipment with bulk handling and mechanical process equipment of other manufacturers.

Both positive-pressure and vacuum, dilute phase systems ranging from single-point "up-and-in" installations to cross-plant systems with multiple pick-up and discharge points and automated controls, fully integrated with other Flexicon equipment and new or existing processes.

Twin cartridge filters with high velocity vacuum fan and reverse-pulse filter cleaning allows continuous, efficient collection of dust when dumping powder and bulk solids from bags, boxes, drums and other containers.

TIP-TITE® models allow dust-free loading, sealing, tipping and discharging. Open-chute models offer economy and easy cleaning. Both accommodate all popular drum sizes.

TIP-TITE® models allow dust-free loading, sealing, tipping and discharging. Open-chute models offer economy and easy cleaning.

Revolutionary design allows fast, easy and dust-free loading, untying, retying and removal of bulk bags. BFF Models feature bag lifting frame for forklift loading. BFC Models feature cantilevered hoist and trolley for loading without a forklift.

Complete systems deliver virtually any bulk material from any upstream source, weigh batch and blend single or multiple ingredients, and deliver the batch to any downstream destination — automatically.

Tubular Cable Conveyors gently slide friable bulk materials through smooth stainless steel tubing using low-friction polymer discs attached to stainless steel cable, allowing single or multiple inlets and outlets, and the routing of conveyor tubing horizontally, vertically or at any angle, through small holes in walls or ceilings.

Flexicon offers three configurations: patented TWIN-CENTERPOST™ fillers* (shown) for low- to medium-capacity and/or sanitary applications where USDA Dairy standards are required; revolutionary SWING-DOWN® fillers for fast, safe bag connections at floor level; and REAR-POST fillers for applications requiring pass-through conveyors and/or powered fill head height adjustment.

Bulk Bag Conditioners loosen bulk solid materials that have solidified during storage and shipment, enabling bulk bag unloaders to discharge the material through bag spouts.

Flexible Screw Conveyors handle virtually any bulk solid material. Depending on model, conveyor tubes can be curved around, over, or under obstructions, and routed through small holes in walls or ceilings. Only one moving part contacts material.