High-velocity vacuum fan draws airborne dust away from the operator through two cartridge filters. Reverse pulse jets automatically return accumulated dust on filter surfaces to the hopper.

BAG DUMP STATIONS

Reverse-Pulse Filter Cleaning for Continuous Operation

Collect dust efficiently

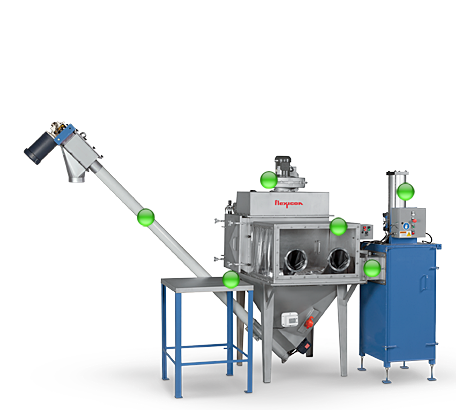

Flexicon bag dump stations (also known as manual dumping stations) collect dust generated when dumping powder and bulk solids from bags, boxes, drums, and other containers, and return the material to the hopper.

The system reduces material waste and eliminates the need to clean a remote dust collection site, while protecting workers and preventing plant contamination.

All units feature a high-velocity vacuum fan that draws airborne dust away from the operator through two cartridge filters that are sized according to the application.

To operate a bag dump station, the hopper lid is opened, the vacuum fan is activated, and material is dumped through the hopper screen. Airborne dust in the vicinity of the

Flexible Screw Conveyors (shown), Tubular Cable Conveyors and Pneumatic Conveying Systems can transport discharged material to any downstream process equipment, packaging line or storage vessel.

Bag infeed chute through the sidewall of the glove box hood allows operator to push empty bags into the bag compactor, causing dust generated from both dumping and compaction to be drawn onto the system's dust collector.

Bags are staged on a stainless steel tabletop and then transferred through a plastic strip curtain into the glove box enclosure.

Large pneumatic air cylinder of compactor compresses bags into a removable bin with 50- to 80-bag capacity.

Glove box enclosure is maintained under negative pressure, preventing the escape of dust through the plastic strip curtain, while containing dust generated during bag opening and dumping activities.

hopper opening is drawn into the dust collector, protecting workers, preventing plant contamination, and reducing material waste.

An automatic reverse-pulse filter cleaning system employs timer-activated solenoid valves to release short blasts of compressed plant air inside the cartridge filters, causing dust build-up on the outer filter surfaces to fall into the hopper. Because the filters are blasted alternately at timed intervals, operation of the dust collection system is both continuous and efficient.

Tailored to your process

The hoppers of Flexicon manual dumping stations are available in various configurations for simplified connection to pneumatic conveyor lines, flexible screw conveyors, and virtually any process equipment.

All units are available in carbon steel with durable industrial finishes, or in stainless steel in industrial or sanitary finishes.

This mobile Flexicon bag dump station incorporates a hinged operator platform, Flexicon flexible screw conveyor, integral bag compactor, and explosion-proof electrical system.

Two cartridge filters are accessed easily by removing the interior baffle, and replaced rapidly without tools using quick-disconnect fittings.

The hoppers of Flexicon bag dump stations are offered with outlets configured for:

Non-flow-through pick-up adapters for single conveying lines

Flexible screw conveyor charging adapters

Rotary airlock valves with flow- through adapters

Universal flanged outlets for direct connection to process equipment

![]()