World's Largest Selection

![]()

![]()

CUT YOUR COSTS

NINE WAYS:

- Slash initial cost

- Cut installation cost

- Save on maintenance

- Use less energy

- Convey at multiple locations

- Save on sanitary construction

- End costly contamination

- Reduce cleaning costs

- Convey disparate materials

with one conveyor

FREE-FLOWING AND NON-FREE-FLOWING MATERIALS AND BLENDS

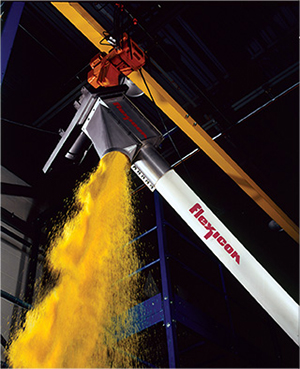

Flexicon flexible screw conveyors (also known as helix conveyors, screw conveyors, spiral conveyors and auger conveyors) offer efficiency and versatility, conveying bulk materials ranging from large pellets to sub-micron powders — both free-flowing and non-free-flowing — with no separation of blended products.

Material discharges from flexible screw conveyor below point at which it is driven, preventing material contact with seals.

MOBILE AND CUSTOM CONFIGURATIONS

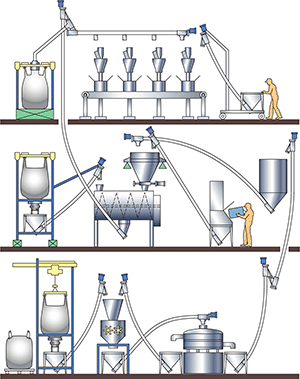

All Flexicon flexible screw conveyors are available on caster-mounted frames with conveyor support masts for in-plant mobility, reducing the need for multiple stationary units.

Both mobile and stationary units are readily customized using interchangeable screws, conveyor tubes, drive motors, hoppers, flow-promotion devices, sensors, controllers, and other components to satisfy the most diverse and demanding end-use requirements.

CLICK FOR MORE INFORMATION ABOUT

MOBILE FLEXIBLE SCREW CONVEYORS

PRINCIPLE

OF OPERATION

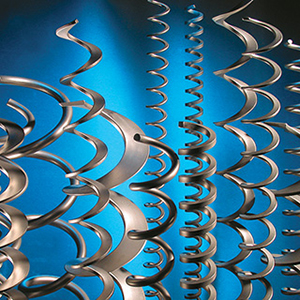

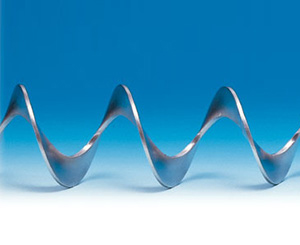

A Flexicon flexible screw conveyor (also known as helix conveyor, screw conveyor, spiral conveyor and auger conveyor) consists of a spring steel or stainless steel flexible screw that is enclosed in a flexible or rigid plastic tube, or a rigid steel tube, and driven by an electric motor normally located at the discharge end of the conveyor. This simple design delivers efficient performance and high reliability while reducing maintenance and cost. When properly engineered according to the specific characteristics of the material being conveyed and the process into which it will be integrated, a flexible screw conveyor can outperform rigid screw conveyors, bucket elevators, drag chain conveyors, aero mechanical conveyors and other equipment intended to transport powder and bulk solid materials.

The intake end of a flexible screw conveyor tube is typically equipped with a charging adapter, a U-shaped trough that connects to the outlet of a hopper or directly to the outlet of process equipment such as a bulk bag discharger, bag dump station, grinder, crusher, screener, blender, reactor or storage vessel of any kind.

Flexicon matches an unequalled number and type of standard and custom flexible screws to a correspondingly wide selection of hopper designs and charging adapters to meet all of your material and process parameters with the greatest efficiency and reliability.

The flexible screw passes through the charging adapter trough, exposing a section of the screw to material flowing into the trough from above. When rotating, the exposed section of screw feeds material into the outer tube, where it is then propelled through the tube by the enclosed portion of the screw.

A phenomenon resulting from the loose fit of a rotating flexible screw within a tube filled with bulk material, is that the screw automatically self-centers within the tube, providing clearance between the screw and tube wall. This affords sufficient space for particles to flow without damage, depending on the fragility and size of particles being conveyed.

A removable clean-out cap covers the intake end of the conveyor tube, permitting rapid emptying and flushing of the tube, as well as disassembly and wash-down of components.

Because the intake end of the screw requires no bearing, and since the discharge end is coupled to the drive motor above and/or beyond the point at which material exits the discharge spout, material does not come in contact with seals or bearings. The flexible screw is therefore the only moving part contacting material.

FLEXIBLE SCREW PIONEERS

Perhaps no other manufacturer has advanced the application of the flexible screw conveyor as far and as fast as Flexicon — the first to introduce 4 1/2 in. (115mm), 6 in. (150mm), and 8 in. (200mm) diameter screw/tube combinations that elevated the capacity of this category of conveyor more than 10-fold in an 8-year period. After more than 25,000 installations worldwide involving a gamut of bulk materials, Flexicon has amassed a wealth of performance data on flexible screws — many of which have been engineered, machined and formed to Flexicon specifications. To you, it means that Flexicon has most likely solved your problem in the most efficient and cost-effective manner possible — or can do so as a matter of routine.

FEATURES

ECONOMICAL TO PURCHASE, INSTALL AND OPERATE

A Flexicon flexible screw conveyor (also known as helix conveyor, screw conveyor, spiral conveyor and auger conveyor) does not require the internal and external components that can make other conveyors expensive to build and operate. The only moving part contacting material is the rugged flexible screw that resists wear and fatigue, resulting in extraordinary reliability and minimal maintenance.

Because the screw and tube are flexible, and can be routed easily in any direction, the intake and discharge can be positioned where you need them, in situations that would be difficult, costly or impossible to satisfy with other conveyors.

HIGH RELIABILITY,

LOW MAINTENANCE

A Flexicon flexible screw conveyor has no internal bearings, cables, filters, chains, buckets, or other potentially problematic components to wear, break down, or require maintenance. The only moving part contacting material is a rugged flexible screw which resists wear and fatigue, and is driven by an electric motor.

Even under a full load of moist, dense product — depending on application parameters — a Flexicon flexible screw conveyor can start and stop repeatedly with no binding or damage to the unit. The result is a conveyor without load limitations that runs dependably, boosting productivity while cutting maintenance.

ONLY ONE MOVING PART

The only part contacting material in a Flexicon flexible screw conveyor is the rugged flexible screw which is driven by an electric motor. As it rotates, the screw propels material and self-centers within the conveyor tube, providing constant clearance between itself and the tube wall.

This simple design does not require cables, chains, disks, internal bearings, and numerous moving parts found in bucket elevators, rigid augers, drag chains, and/or aeromechanical conveyors — parts that can add initial cost, require maintenance, wear out, breed contamination, and/or break down.

CONVEY IN ANY DIRECTION

Whereas many conveyors (such as rigid screw conveyor, bucket elevator, drag chain conveyor and aero mechanical conveyor designs) have limited angles of incline and/or straight-only conveying paths, Flexicon flexible screw conveyors can move material vertically, horizontally, or at any angle — over, under, or around obstructions, through small holes in walls or ceilings.

GENTLE PRODUCT

HANDLING AND BLENDING

Flexicon flexible screw conveyors can handle your products gently, because the flexible screw self-centers as it rotates. This can provide ample clearance between the screw and tube wall to prevent grinding, crushing, and other product damage.

In addition, the gentle rolling action created by the screw prevents the separation of blends throughout the entire length of the conveyor.

CLEANLINESS

ENCLOSED TUBE PREVENTS CONTAMINATION

A Flexicon flexible screw conveyor (also known as helix conveyor, screw conveyor, spiral conveyor and auger conveyor) is totally enclosed, dust-free, and mess-free, preventing contamination of your bulk products and plant environment, while preserving the moisture and temperature levels of materials being conveyed.

Compare the smooth interior surfaces of a Flexicon flexible screw conveyor with potential contamination sources found in other conveyors, and you may specify the Flexicon flexible screw conveyor on the basis of product purity alone.

Sanitary Mobile Flexible Screw Conveyor tilts down for fast, easy cleaning. Fits through narrow aisles and around corners.

Sanitary low incline Flexible Screw Conveyor meets 3-A Dairy standards.

FAST, THOROUGH CLEANING

A Flexicon flexible screw conveyor has no internal cracks, crevices or bearings that can trap particles or prevent thorough cleaning. Simply remove the clean-out cap and reverse rotation to evacuate any residual material prior to flushing with air, water, steam, or cleaning solution. The screw and tube can be removed quickly for easy and thorough cleaning.

DESIGN, CONSTRUCTION

AND FINISHES SATISFY CLEANLINESS STANDARDS

Flexicon conveyors, as well as most other Flexicon equipment, are available in carbon steel with a variety of durable industrial finishes, or stainless steel finished to industrial, food, dairy, or pharmaceutical standards, including designed and constructed for 3-A compliance.

OPTIONS

BEV-CON™ CONVEYORS MOVE NON-FREE-FLOWING MATERIALS

In addition to the attributes of other Flexicon Flexible Screw Conveyors, BEV-CON™ conveyors can move powder and bulk solid materials that tend to pack, cake, smear, plug, fluidize, separate, or are otherwise difficult-to-handle.

This high capacity BEV-CON conveyor is equipped with a highly-specialized flexible screw matched to material characteristics and other application requirements.

BEV-CON conveyors are also highly effective for handling fragile or brittle products that tend to break or crumble from the friction, crushing, grinding, pressure, or impact that can occur in other conveyors. Products ideally suited to the special capabilities of a BEV-CON conveyor range from sub-micron powders to large pellets and include:

-

CHEMICALS:

Titanium dioxide, carbon black, calcium carbonate, powdered lime, rubber, detergent powders and sulfur -

FOODS:

Cake mixes, soup mixes, gravy mixes, cocoa powder, cheese, candy, milk powder, dehydrated, frozen or raw vegetables, fruits and nuts -

PHARMACEUTICALS AND COSMETICS:

Talc, titanium dioxide, zinc oxide, clay, calcium carbonate, powder and finished bulk of all types

Moist, sticky materials; Friable materials;

Products that pack, cake, smear, or plug.

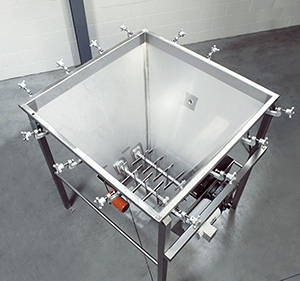

HOPPERS THAT PROMOTE FLOW

Flexicon's High Flow Hopper, purpose-built for flexible screw conveyors, increases the flow of both free- and non-free-flowing bulk materials while eliminating or decreasing the amount of residual material in the hopper as well as the need for flow promotion devices.

The hopper is designed with a steep backwall and diametrically opposed sidewalls having panel sections which are skewed outward on a horizontal axis, forming a trapezoidal area. The divergent angles reduce the ability of non-free-flowing materials to establish a bridge between the hopper sidewalls, instead causing material to topple and flow toward and down the steep backwall.

The hopper walls converge to form a trapezoidal inlet to the conveyor interface adapter which also employs shear planes and vertical walls, to direct material into a rotating flexible screw more positively than with previous rectangular interface adapters.

The passive flow promotion attributes of the new hopper can eliminate the need for flow promotion devices such as vibrators and agitators.

The new configuration also increases usable hopper capacity by 5 to 19 percent, while reducing residual material in the hopper by 90 to 100 percent, depending on material flow characteristics.

VOLUMETRIC FEEDING

Flexicon flexible screw conveyors with volumetric feeding controls provide simultaneous metering and conveying of bulk solid products. The units are equipped with AC or DC variable speed drives and hoppers with flow promotion devices for continuous feeding of both free-and non-free-flowing materials.