DRUM-BOX-CONTAINER DUMPERS

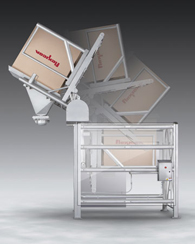

Sanitary Box Dumper

This TIP-TITE® Sanitary Box Dumper forms a dust-tight seal between the container and the equipment, tips the container, and discharges bulk material at controlled rates.The unit is intended for dumping of bulk foods, pharmaceuticals and contamination-sensitive chemicals from boxes weighing up to 2500 lbs (1134 kg) and measuring 36 to 48 in. (915 to 1220 mm) on a side and 39 to 44 in. (990 to 1117 mm) in height.

The container platform is raised by dual hydraulic cylinders, creating a dust-tight seal between the top edge of a box and the underside of a discharge hood.

Twin hydraulic cylinders then pivot the platform-hood assembly, with dust-tight seal intact, to 45, 60 or 90 degrees beyond horizontal, including a motion-dampening feature at the termination of container rotation. A pneumatically-actuated slide gate at the discharge end of the cone controls the flow of material into storage vessels or process equipment.

An optional, gasketted discharge gate actuated by twin pneumatic cylinders, provides a large opening with chute for the passage of larger objects or non-free-flowing bulk solids that may otherwise bridge across smaller openings, and allows control of the material discharge.

The dumper is constructed of stainless steel with continuous welds ground and polished to sanitary standards. All horizontal frame members are fabricated of round stainless steel tubing to promote water run-off in wash-down environments. Other sanitary features include capped threads, sloped-top control enclosures, guarding standoff brackets and FDA-approved epoxy paint on hydraulic cylinders.

It is also available constructed of carbon steel with durable industrial coatings for dumping of dry solids, sludges and slurries from boxes, drums and other containers in less stringent environments, and is available configured with Flexicon mechanical or pneumatic conveyors to transport discharged material to any plant location.

TIP-TITE® Sanitary Box Dumper forms a gasketted, dust-tight connection between the container and the equipment, tips the container to 45, 60, or 90 degrees past horizontal, and discharges bulk material through a slide gate at controlled rates.

AA-1182