CONFIGURATIONS

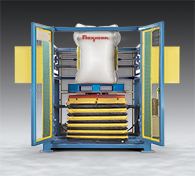

Bulk Bag Conditioner for Mining Applications

This Hydraulic Bulk Bag Conditioner from Flexicon Corporation loosens dry additives such as ammonium nitrate, urea, lime, and other hygroscopic chemicals and bulk mining materials that have solidified during storage or transport, enabling previously solidified product to flow from bulk bags.The conditioner features two hydraulic rams with specially contoured end plates to press opposing sides of bulk bags. Bulk bags can be raised, lowered, and rotated for complete conditioning of the bag on all sides at all heights, using automated turntables and scissor lifts, or electric hoist and trolley assemblies. The number and pressure of hydraulic ram actuations, the height of the turntable, and the degree of rotation are user adjustable, making it gentle on bag fabric.

The system controller and hydraulic pump can be mounted on the exterior of the safety cage or remotely. The conditioner is fully enclosed on all four sides for operator safety and includes full-height doors that are interlocked to disallow operation of the system when the doors are open. Available in diesel or electric models, this bulk bag conditioner is constructed of heavy-duty, weatherproof stainless steel, and is suitable for Zone 1-2, 21-22 and other hazardous area installations.

Available as a stand-alone unit or integral component of a bulk bag discharger, mobile or stationary, the unit measures 87" (2210 mm) H x 133" (3378 mm) W x 78" (1981 mm) D. It features heavy-duty construction, accommodates bulk bags of all popular sizes, and requires only an electrical power connection for operation.

U-1084M