BULK BAG FILLERS

Standard Features Include:

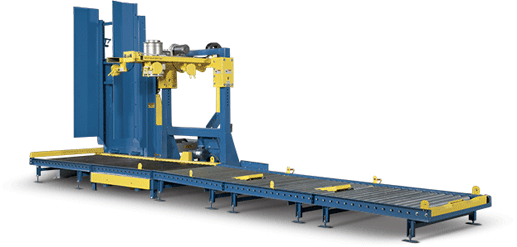

- Rugged TWIN-CENTERPOST™, REAR-POST, SWING-DOWN® or BASIC FILLER configuration

- Forklift fill head height adjustment to accommodate all popular bag sizes

- Inflatable collar to hold and seal the bag inlet spout

- Pneumatically retractable bag strap hooks for quick, positive strap release (optional on Basic Filler)

- Vent port for air displacement and dust control

Optional Features Include:

- Accurate weigh scale system with automated control

- Automated vibratory densification/ deaeration system to stabilize the bag

- Inflator to expand empty bag and liner, and remove creases prior to filling

- Pneumatically actuated material flow control valve

- Custom controls for integrated material feed system

- Drum/box filling conversion kit

- Powered fill head height adjustment (REAR-POST and SWING-DOWN® fillers only)

- Powered or gravity roller conveyor for bulk bag staging and removal

- Pallet-jack accessible base

Optional bag inflator removes creases prior to filling. SWING-DOWN® filler shown. Also available on TWIN-CENTERPOST™ and REAR-POST fillers.

Flexicon's Low Profile Bulk Bag Filler allows removal of loaded bags using a pallet jack, eliminating the need for a forklift.

Patented TWIN-CENTERPOST™ Bulk Bag Fillers* are available in USDA Dairy Accepted construction and finish.

Optional powered or gravity roller conveyors allow rapid staging and removal of bulk bags. REAR-POST filler shown. Also available on TWIN-CENTERPOST™ and SWING-DOWN® fillers.

*Patent(s) granted and/or pending.