Click to enlarge

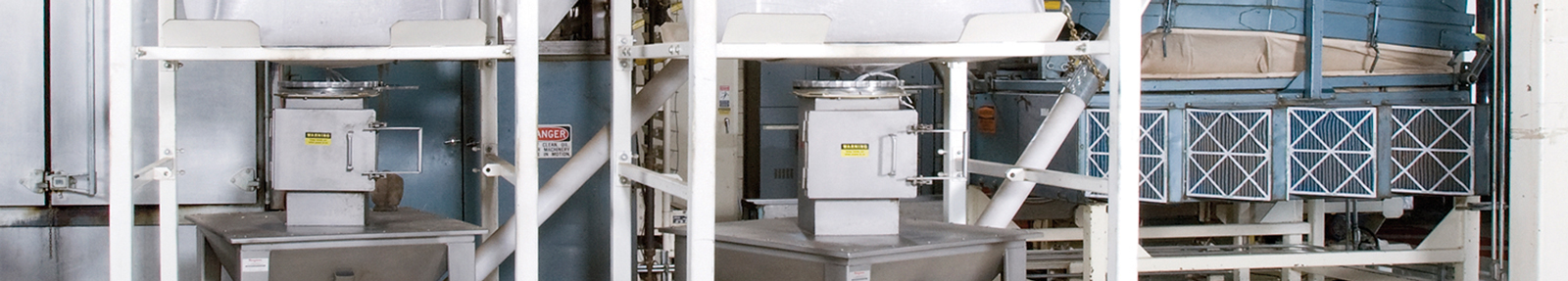

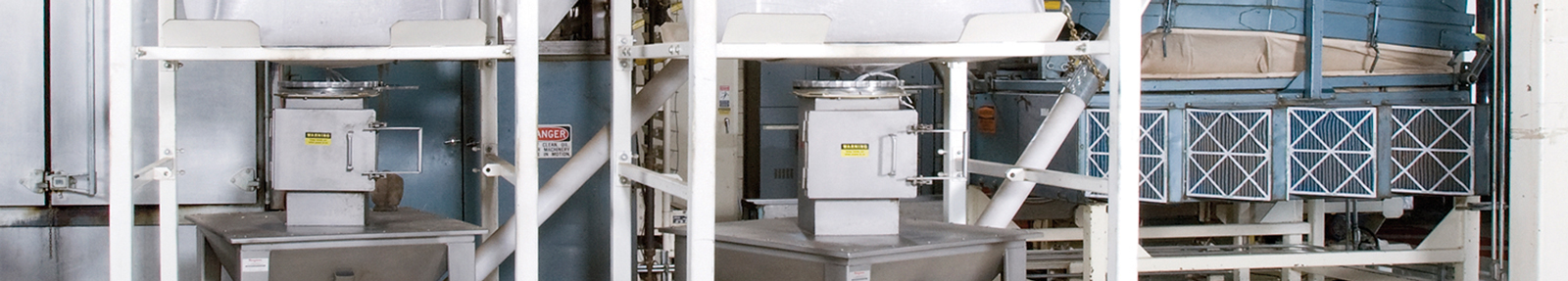

Click to enlargeTwo bulk bag unloaders, each with a 25 ft (7.6 m) long flexible screw conveyor, maintain a continuous flow of shelled peanuts to the gas-fired roaster in background. The fully enclosed system enhances plant sanitation and reduces manual handling.

Click to enlarge

Click to enlargeOperator forklift-loads bag-lifting frame onto the bulk bag unloader.

Click to enlarge

Click to enlargePeanuts are discharged from the bulk bag into the receiving hopper through a manually operated 12 in. (305 mm) dia iris valve attached to the bag spout.

Click to enlarge

Click to enlargeEach 25 ft (7.6 m) long flexible screw conveyor consists of a rotating, stainless steel spiral screw, housed in a 4.5 in. (115 mm) O.D. polymer tube.

Click to enlarge

Click to enlargeEach flexible screw conveyor empties peanuts (through a discharge adapter and flexible downspout) into a surge hopper from which they are conveyed to the roaster.

Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge