Click to enlarge

Click to enlargeA 30 ft (9 m) long flexible screw conveyor transfers aluminum powder from a bag dump station to a gain-in-weight hopper on the mezzanine.

Click to enlarge

Click to enlargeDust generated by operator splitting and dumping of bags is contained by dust collector of bag dump station.

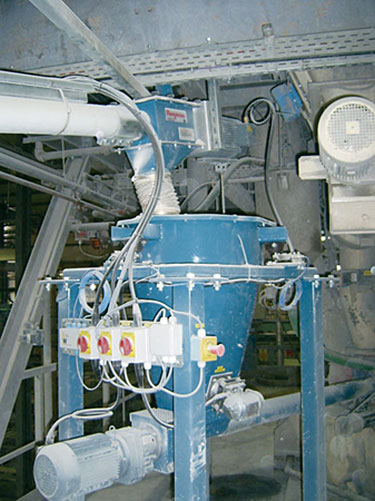

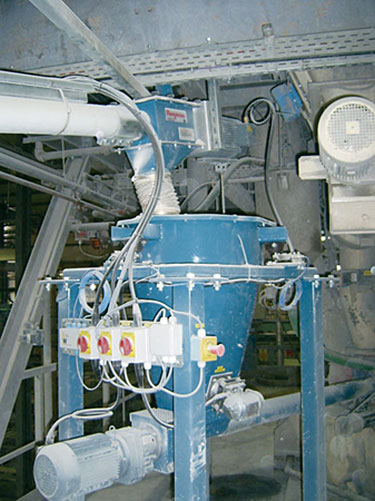

Click to enlarge

Click to enlargeThe upper flexible screw conveyor transfers aluminum powder from the bag dump station to the top of a weigh hopper, while the conveyor below feeds weighed batches to the blender.

Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge