SANITARY CONSTRUCTION AND FINISHES

Virtually all Flexicon equipment is available constructed and finished to meet food, dairy and pharmaceutical requirements of industry associations and governmental agencies worldwide.

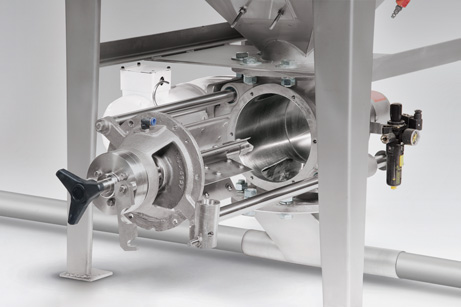

Flexicon sanitary equipment can be constructed almost entirely of 304 or 316 stainless steel and finished to Flexicon sanitary standards, or customer-specified requirements. Product contact areas include continuous welds, ground smooth and flush with contiguous walls, with available finish levels up to mirror finish.

Wash down control enclosures (NEMA 4 or NEMA 4X) and motors allow fast, thorough wash down using steam, cleaning solutions and high pressure water, with no adverse effect on equipment.

Sanitary designs

Beyond requisite sanitary construction and finishes, Flexicon equipment offers innovative design features — many patented — that enable food, dairy and pharmaceutical processors to minimize washdown time, eliminate cross-contamination between changeovers, eliminate plant contamination and verify cleanliness — and do so rapidly, efficiently and safely.