BULK BAG FILLERS

Your Bulk Bag Filler is Only as Reliable as Your Material Delivery System

CHOOSE FROM THREE MATERIAL DELIVERY SYSTEMS

Flexicon will custom engineer an automated delivery system according to your specific bulk material and process requirements. Whether your system must integrate with new or existing upstream equipment, elevate non-free-flowing materials, or prevent the surging of free-flowing materials from elevated storage vessels, Flexicon can provide the ideal system to feed your filler:

- Flexible screw conveyors

- Pneumatic conveyors

- Tubular cable conveyors

- Controls and weighing systems

- Conveyor and feeder inlet adapters to interface with material sources

- Surge bins and other storage vessels for overhead material delivery

Bulk bag filler fed by PNEUMATI-CON® Pneumatic Conveying Systems

Bulk bag filler fed by FLEXICON® Flexible Screw Conveyor

Bulk bag filler fed by FLEXI-DISC® Tubular Cable Conveyor

CHOOSE FROM THREE WEIGHING METHODS FOR LOW- TO HIGH-CAPACITY APPLICATIONS

LOW CAPACITY:

PLANT SCALE

TWIN-CENTERPOST™ Bulk Bag Fillers can be forklifted onto an all-purpose plant scale, eliminating the cost of load cells and controls.

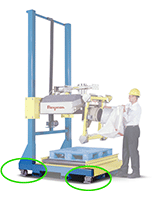

LOW TO MEDIUM/HIGH CAPACITY:

FILLER ON LOAD CELLS

All Flexicon Bulk Bag Fillers are available mounted on load cells that transmit weight-gain signals to a controller which slows and then stops an optional conveyor (or rotary valve) once an accurate fill weight is reached. (Flexicon® Flexible Screw Conveyor shown. FLEXI-DISC® Tubular Cable Conveyor and PNEUMATI-CON® Pneumatic Conveying Systems also available.)

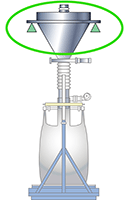

MEDIUM TO HIGH CAPACITY:

WEIGH HOPPER ABOVE FILLER

Weigh hoppers suspended above the bulk bag filler allow simultaneous recharging of the hopper and replacement of the bulk bag for filling rates up to 20 per hour.

*Patent(s) granted and/or pending.