BAG ACTIVATORS

Pneumatically-actuated FLOW-FLEXER® bag activators promote material flow through bag spouts. Also available are Bulk Bag Conditioners integral to Bulk Bag Dischargers for loosening materials solidified in bulk bags.

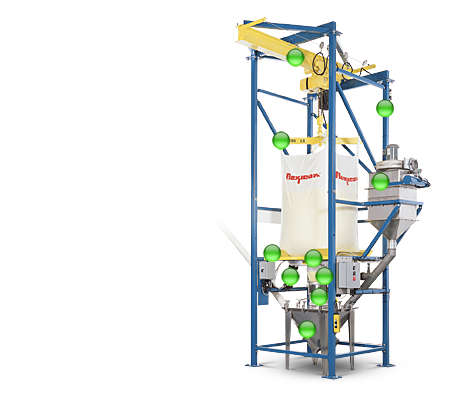

Flexicon BULK-OUT® Bulk Bag Dischargers (also known as FIBC, Big Bag and Jumbo Bag unloaders) are offered in numerous frame configurations. The two most popular are BFF Series dischargers with bag lifting frame for forklift loading and unloading of bulk bags, and BFC Series dischargers with cantilevered I-beam, electric hoist and trolley for loading and unloading of bulk bags without the use of a forklift.

Other bulk bag unloader configurations include split frames for forklift loading of bags in low headroom areas, half frames for suspending bags during discharge using a forklift, continuous loss-of-weight dischargers for uninterrupted feeding directly from bulk bags, and other designs satisfying highly specialized requirements.

Pneumatically-actuated FLOW-FLEXER® bag activators promote material flow through bag spouts. Also available are Bulk Bag Conditioners integral to Bulk Bag Dischargers for loosening materials solidified in bulk bags.

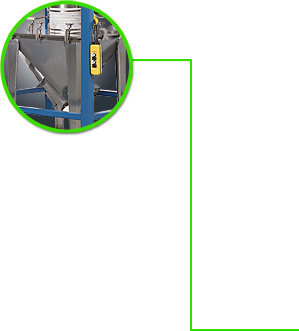

Hoppers in a wide variety of designs connect to processing equipment, pneumatic or mechanical conveyors. Available with hinged lid for manual dumping or clamped lid (shown) for rapid wash-down.

TELE-TUBE® telescoping tube prevents dead spots and promotes flow.

Frames are offered in carbon steel with durable industrial finishes or in stainless steel designed and constructed to industrial, food, dairy or pharmaceutical standards.

Cantilevered I-beam with electric hoist and trolley allows positioning of bulk bag without the use of a forklift.

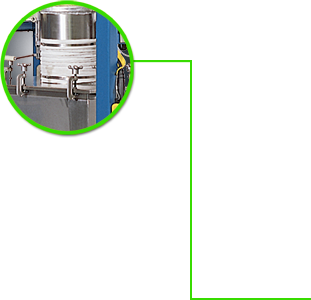

Patented SPOUT-LOCK® clamp ring eliminates dust during untying and discharge.

Patented POWER-CINCHER® flow control valve cinches the bag spout concentrically.

BAG-VAC® dust collector creates negative pressure within sealed system, collapsing empty bags prior to tie-off and removal, eliminating dust associated with manual flattening of empty bags.

Operators are protected from falling bags by four safety frame cross members, and four guard plates.

Patented Z-CLIP™ bag strap holder allows fast, easy and secure insertion and removal of bag straps.

All BULK-OUT® Bulk Bag Dischargers are offered with a broad range of innovative accessories (many patented), delivering an unprecedented level of efficiency, cleanliness and economy. A range of integral flow promotion devices is available, as are dedicated bulk bag conditioners that loosen bulk solid materials that have solidified during storage and shipment, enabling bulk bag unloaders to discharge the material through bag spouts.

Just as bulk bags changed the way bulk material was stored and shipped over the last decade, so will these bulk bag dischargers revolutionize the way you load, untie, retie, remove and collapse bulk bags in the future.

No longer must your operators reach through cramped access doors and awkward glove boxes, struggle to retie partially empty bags, clean up spillage after disconnections, dislodge products from dead spots or flatten bags manually.

Flexicon's latest generation of bulk bag dischargers can eliminate the drawbacks of outdated designs while dramatically improving convenience, safety and cleanliness. The heart of the new design is a bag spout interface that not only creates a dust-tight seal, but promotes material flow and total evacuation. It also allows easy retying of partially empty bags, and can collapse empty bags—free of spillage and dust.